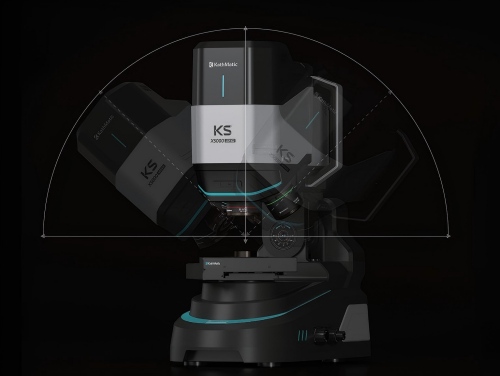

ULTRA DOF 3D DIGITAL MICROSCOPE

The Ultra Depth of Field 3D Digital Microscope (ULTRA DOF 3D DIGITAL MICROSCOPE) is widely used in scenarios such as electronics manufacturing, materials research, and precision inspection. Its core R&D technology achieves high-definition 3D imaging across a large depth of field. The product has established collaborative cases with several leading technology companies for applications like chip solder joint inspection and microstructure analysis. Supported by automated production lines and strict quality control, it boasts strong manufacturing capabilities and maintains leading annual sales figures. Currently, with sufficient inventory levels, it can respond swiftly to market demands, providing reliable tools for industrial quality control and scientific research exploration.

- HC

- CHINA

- 1 MONTH

- 200/ MONTH

- Information

- Download

The Ultra Depth of Field 3D Digital Microscope (ULTRA DOF 3D DIGITAL MICROSCOPE) plays a crucial role in modern industrial inspection and scientific research. This Ultra Depth of Field 3D Digital Microscope provides a revolutionary solution for micro- and nano-scale observation, thanks to its exceptional optical design and 3D reconstruction algorithms. The core advantage of the Ultra Depth of Field 3D Digital Microscope lies in its ability to acquire complete three-dimensional topography data of a sample across a large depth of field in a single capture, completely addressing the pain point of traditional microscopes requiring constant refocusing when observing samples with significant height variations. Therefore, the Ultra Depth of Field 3D Digital Microscope has become an indispensable quality control tool in the field of precision manufacturing.

The application of the Ultra Depth of Field 3D Digital Microscope is particularly prominent in the electronics manufacturing industry. For instance, in chip packaging processes, the Ultra Depth of Field 3D Digital Microscope is used for rapid and precise three-dimensional measurement of solder ball height, coplanarity, and solder joint defects. The Ultra Depth of Field 3D Digital Microscope can provide not only clear two-dimensional images but also generate high-precision 3D point cloud data, enabling engineers to quantitatively analyze soldering quality, thereby effectively improving product yield. Many leading semiconductor companies have incorporated the Ultra Depth of Field 3D Digital Microscope into their standard inspection procedures, which fully demonstrates the value of the Ultra Depth of Field 3D Digital Microscope in high-end manufacturing.

The development of the Ultra Depth of Field 3D Digital Microscope integrates multiple cutting-edge technologies. To ensure the imaging performance of the Ultra Depth of Field 3D Digital Microscope, the R&D team has conducted in-depth research in areas such as depth of field extension algorithms, high-precision motorized stage control, and the integration of high-performance image sensors. The proprietary software algorithm adopted by the Ultra Depth of Field 3D Digital Microscope can intelligently synthesize images from different focal planes and construct detailed 3D models. This allows the Ultra Depth of Field 3D Digital Microscope to reliably output inspection results even when faced with complex samples featuring high reflectivity or low contrast.

Strong production capabilities guarantee the stable delivery of the Ultra Depth of Field 3D Digital Microscope. The production line is equipped with high-precision assembly and calibration equipment, ensuring that every Ultra Depth of Field 3D Digital Microscope shipped meets stringent performance standards. By introducing automated testing processes, the production efficiency and consistency of the Ultra Depth of Field 3D Digital Microscope have been greatly enhanced. Currently, the production capacity of the Ultra Depth of Field 3D Digital Microscope can fully meet global market demand, with sufficient inventory and backup stock, enabling rapid product supply and technical support services for customers.