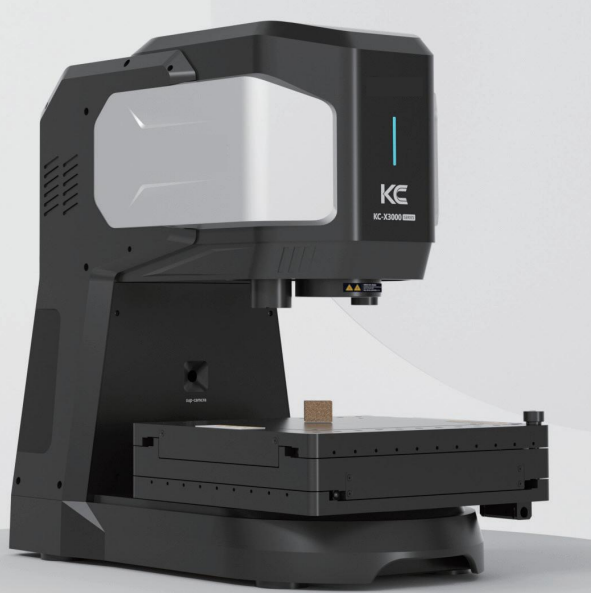

3 IN 1 PRECISION MEASURING MICROSCOPE

The 3-in-1 precision measuring microscope integrates observation, measurement, and real-time analysis, serving critical roles in semiconductor, precision manufacturing, and R&D sectors. It employs high-resolution optics and intelligent imaging, with proven applications in chip packaging and microstructure inspection through partnerships with leading electronics firms. Supported by automated production and rigorous quality control, the instrument ensures reliable performance and stable supply. Sales have grown steadily, supported by efficient inventory management that enables prompt market response and dependable precision measurement solutions.

- HC

- CHINA

- 1 MONTH

- 200/ MONTH

- Information

- Download

3-in-1 Precision Measuring Microscope: The Core Solution for Integrated Precision Measurement

In today's advanced manufacturing and scientific research fields, where extremely high precision is required, the 3-in-1 precision measuring microscope, as an integrated measuring instrument, plays an indispensable role. This 3-in-1 precision measuring microscope seamlessly integrates three major functional modules: high-magnification morphology observation, micron-level dimensional measurement, and dynamic real-time analysis, providing unprecedented efficiency and accuracy for precision inspection tasks. Whether it is defect inspection of semiconductor wafers or contour mapping of precision mechanical parts, this 3-in-1 precision measuring microscope can complete the tasks on a unified platform, avoiding the sample displacement errors and data alignment challenges associated with switching between traditional methods. Therefore, many manufacturing enterprises striving for exceptional quality have come to regard this 3-in-1 precision measuring microscope as an indispensable standard configuration within their quality control systems.

Technical Architecture and Core Competitive Advantages

From a technical implementation perspective, the performance advantages of the 3-in-1 precision measuring microscope are rooted in its advanced optical design and intelligent software algorithms. The optical system of the 3-in-1 precision measuring microscope employs apochromatic objectives and coaxial illumination technology, ensuring the acquisition of clear-edged, detail-rich, and true-to-life images even when observing various highly reflective or low-contrast samples. Simultaneously, the built-in intelligent image processing unit of the 3-in-1 precision measuring microscope can automatically identify feature regions and perform sub-pixel edge extraction, thereby controlling measurement repeatability at the nanometer level. It is precisely the integration of these core technologies that enables the 3-in-1 precision measuring microscope to demonstrate stability and reliability surpassing that of single-function devices when confronting complex and precise measurement challenges. Market feedback indicates that users who adopt the 3-in-1 precision measuring microscope experience significant improvements in both product yield and R&D efficiency.

Diverse Application Scenarios and Deepening Industry Collaboration

The application scenarios of the 3-in-1 precision measuring microscope have rapidly expanded from traditional laboratory research to online inspection on industrial production lines. In the consumer electronics industry, the 3-in-1 precision measuring microscope is used to inspect the structural dimensions and assembly gaps of smartphone camera modules; in the new energy sector, the 3-in-1 precision measuring microscope assists researchers in accurately measuring the microscopic morphology and coating thickness of battery electrode materials. Many industry leaders choose to establish in-depth collaborations with the manufacturers of the 3-in-1 precision measuring microscope to jointly develop customized measurement solutions. For example, a globally renowned automotive component supplier introduced the 3-in-1 precision measuring microscope for 100% full inspection of precision gears on automated production lines, significantly enhancing production cycle time and quality control consistency. These successful collaboration cases strongly demonstrate the powerful adaptability and value of the 3-in-1 precision measuring microscope across various industrial settings.

Production Assurance and Market Responsiveness

To ensure that every 3-in-1 precision measuring microscope delivered to customers meets the promised performance standards, the manufacturer has built a vertically integrated production capability, ranging from core component machining to final assembly and calibration of the complete unit. The production line for the 3-in-1 precision measuring microscope integrates high-precision CNC machine tools and automated calibration equipment, with the assembly and adjustment of key optical components conducted in a constant-temperature, constant-humidity, ultra-clean environment. Stringent process flows and quality control systems form the foundation for the long-term stable operation of this 3-in-1 precision measuring microscope. In response to the growing global market demand, the manufacturer of the 3-in-1 precision measuring microscope maintains reasonable inventory levels and agile supply cycles through scientific supply chain management and production planning. This means that when customers need to introduce or expand their inspection capabilities with the 3-in-1 precision measuring microscope, the manufacturer can respond swiftly, ensuring smooth project progression without delays in production or R&D processes due to equipment delivery issues.