The Secret to an EV's Long Range Lies in Its Unseen Precision Parts

2025-12-12 15:47The Secret to an EV's Long Range Lies in Its Unseen Precision Parts

1. Beyond the Battery: How Precision Components Maximize Energy Efficiency

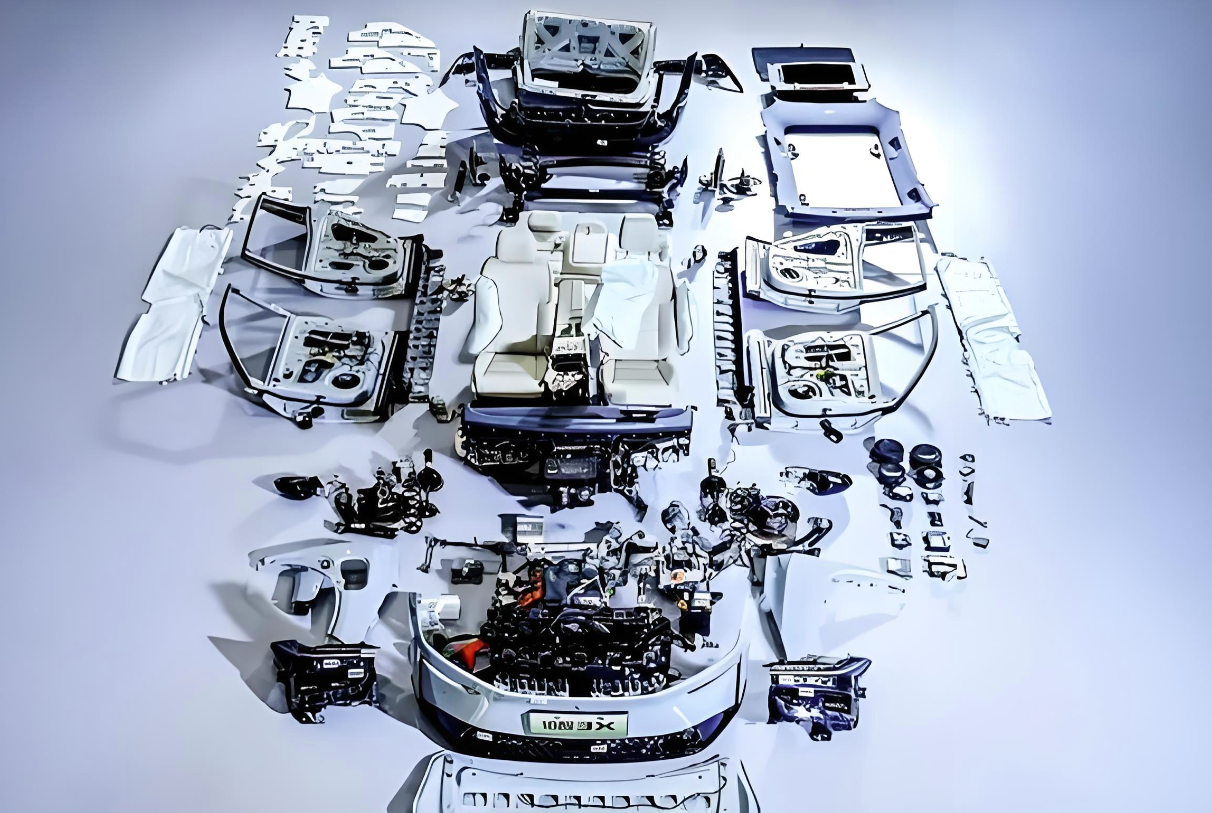

The common narrative around electric vehicle (EV) range focuses almost exclusively on battery capacity. However, even the most powerful battery's energy is wasted if the components that transfer and use that electricity are inefficient. This is where the unseen world of ultra-precision manufacturing becomes critical. Components like motor laminations, power electronics, and thermal management parts, manufactured with micron-level accuracy, play a pivotal role in minimizing energy loss. For instance, high-precision tolerance accommodation in motor stators and rotors ensures optimal magnetic flux, reducing eddy currents and heat generation. Similarly, perfectly sealed pipes and flow controllers in the cooling system ensure that batteries and motors operate within their ideal temperature range, preventing efficiency drops due to overheating. By minimizing energy loss at every stage—from the battery to the wheels—these precision components directly translate into more miles per charge, unlocking the true potential of the battery pack.

2. The Role of Advanced Metrology in Guaranteeing Component Performance

How can manufacturers consistently achieve such high levels of precision and quality? The answer lies in the deployment of sophisticated measurement solutions during the production process. Companies like InnovaMeld provide the essential technology to verify that every component meets exact specifications. Coordinate Measuring Machines (CMMs) perform exhaustive 3D scans of parts like complex motor housings or inverter casings to validate their geometry against digital designs. Roundness testers and cylindricity measuring machines ensure that rotating elements within the motor and drive system are perfectly balanced, minimizing vibration and mechanical energy loss. Furthermore, automatic video measuring machines enable 100% inspection of high-volume components like sensor assemblies, ensuring zero defects and flawless functionality. This relentless pursuit of measurement accuracy is not just about quality control; it's a fundamental enabler of the energy efficiency and long-range performance that define the next generation of EVs.

3. Lightweighting and Integration: The Future of EV Innovation

The quest for longer range also drives innovation in lightweighting and component integration. Every gram saved reduces the energy required for acceleration, directly extending range. Here, precision manufacturing enables the production of incredibly strong yet ultra-thin parts. Techniques like micron injection molding allow for the creation of complex connectors and housings that are both lightweight and durable. Moreover, the trend is moving towards highly integrated systems, where multiple functions are combined into a single, compact unit to save space and weight. The expertise in designing and measuring these integrated systems, such as combining a motor controller with a cooling manifold, is crucial. This requires a comprehensive production management system that oversees everything from logistics optimization to quality management, ensuring that these advanced, lightweight components are produced reliably and at scale. This holistic approach to manufacturing is what will continue to push the boundaries of EV performance.

Conclusion

In summary, the secret to extending an EV's range is a holistic engineering effort that goes far beyond the battery cell. It is achieved through the synergistic combination of energy-efficient precision components, verified by advanced metrology technology, and assembled into lightweight, integrated systems. As the EV industry evolves, the relentless innovation in these unseen, high-precision parts will remain the true driver of performance and efficiency.