The Role of Ultra-Precise CMMs in Advancing Electric Vehicle (EV) Manufacturing Quality

2025-12-14 16:04The Role of Ultra-Precise CMMs in Advancing Electric Vehicle (EV) Manufacturing Quality

1. Ensuring Powertrain Perfection: Measuring Critical E-Axle and Battery Components

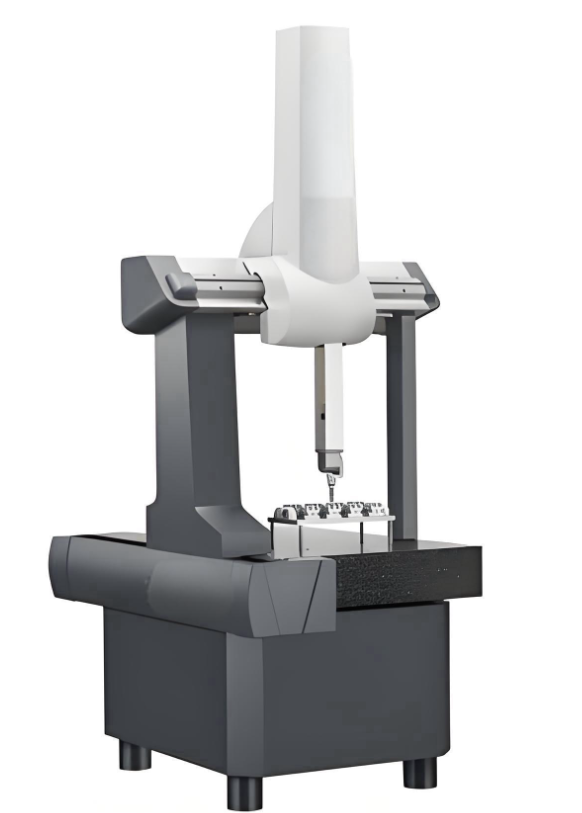

The heart of an electric vehicle's performance lies in its powertrain and battery system. These components demand exceptional precision to operate efficiently, reliably, and safely. Ultra-precise Coordinate Measuring Machines (CMMs) are indispensable in validating the complex geometries of these parts. For instance, the housing of an e-axle—which integrates the motor, gearbox, and inverter—must have perfect bearing bore alignment and flatness to minimize friction and prevent premature wear. Even a micron-level deviation can lead to significant energy loss, noise, and vibration. Similarly, CMMs are used to measure the precise dimensions and locations of cooling channels within battery trays, ensuring optimal thermal management. By providing volumetric accuracy through high-density 3D scanning, CMMs guarantee that these critical components meet the stringent dimensional verification standards required for maximum energy efficiency and long-term durability in EVs.

2. Validating Lightweight Structures and Complex Assemblies

Electric vehicles rely on lightweight materials like aluminum and high-strength steel, as well as complex multi-part assemblies, to maximize range without compromising safety. This poses a significant quality control challenge. Here, CMMs with high measurement precision excel at validating large body-in-white (BIW) components, chassis parts, and intricate sub-assemblies. They can quickly measure the fit and form of these structures, ensuring that all components interface correctly. This is crucial for achieving the structural integrity needed for crash safety and for eliminating unwanted wind noise by ensuring perfect door and panel gaps. The ability of CMMs to perform comprehensive 3D inspection of both individual parts and full assemblies makes them vital for maintaining the geometric tolerances that define the quality, safety, and acoustic comfort of modern electric vehicles.

3. The Backbone of a Data-Driven, Zero-Defect Manufacturing Process

Beyond simple measurement, modern CMMs are the cornerstone of a proactive, data-driven quality strategy. They are integrated directly into the digital thread of smart factories. The measurement data collected by CMMs is fed into Statistical Process Control (SPC) software, allowing manufacturers to monitor production trends in real-time and identify potential deviations long before they lead to scrap or rework. This capability for predictive quality analysis is essential for achieving the zero-defect manufacturing goals that EV makers strive for. Furthermore, the high repeatability and reproducibility (R&R) of ultra-precise CMMs ensures that measurements are consistent across different machines, shifts, and global production facilities. This level of industrial quality control not only elevates the final product but also builds a foundation of trust and reliability for the entire EV supply chain.

Conclusion

In conclusion, ultra-precise CMMs are far more than just quality control tools; they are fundamental enablers of the EV revolution. By guaranteeing the accuracy of powertrain components, validating the integrity of lightweight structures, and providing the data backbone for a zero-defect manufacturing philosophy, CMMs play a critical role in advancing the quality, performance, and reliability that define the next generation of electric vehicles.