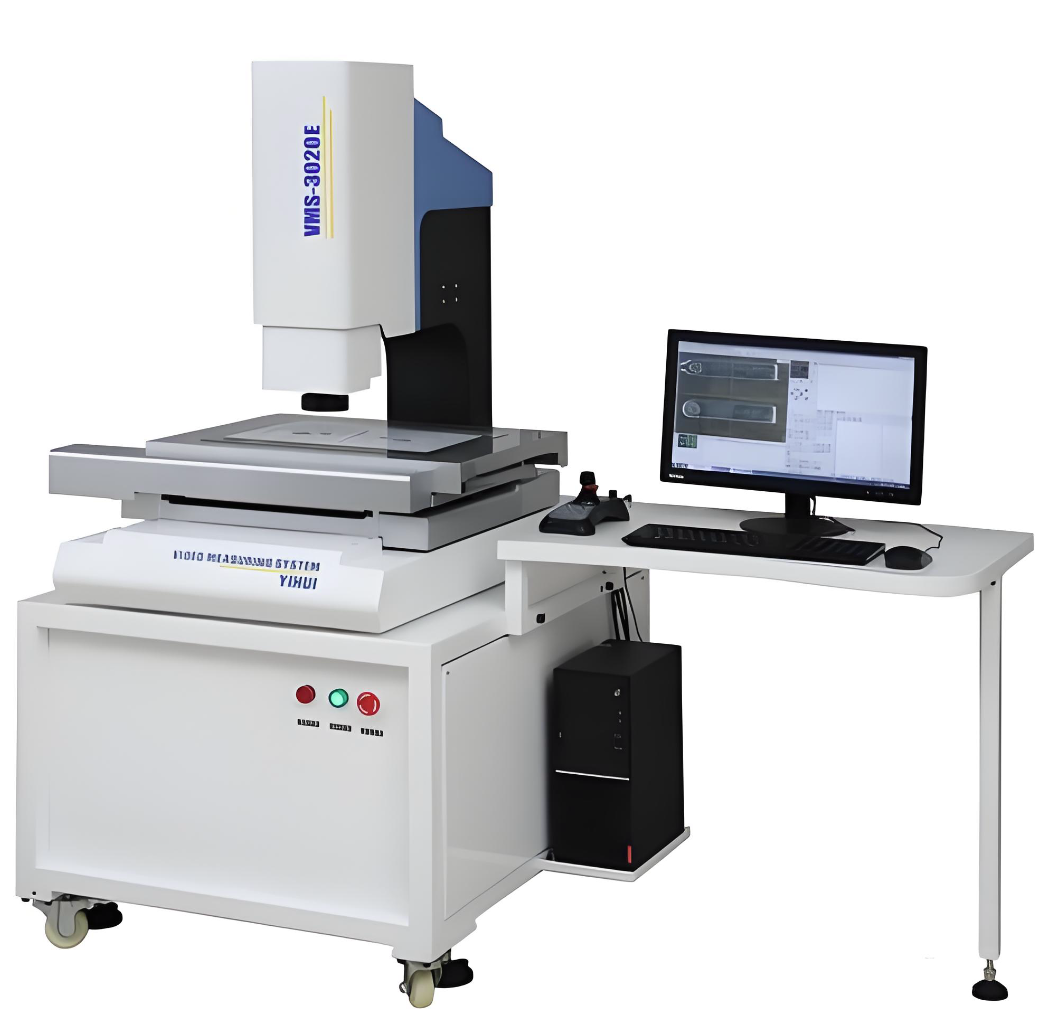

Ensuring Zero Defects: The Technology Behind Automatic Video Measuring Machines for High-Volume Production

2025-12-13 15:56Ensuring Zero Defects: The Technology Behind Automatic Video Measuring Machines for High-Volume Production

1. The Engine of Accuracy: Advanced Optics and Intelligent Illumination

At the heart of any Automatic Video Measuring Machine (VMM) lies its ability to see with unparalleled clarity and consistency. This is achieved through a combination of high-resolution cameras, precision optics, and programmable, multi-directional LED illumination systems. The high-resolution camera acts as the machine's eye, capturing minute details of the workpiece. However, the true differentiator is intelligent illumination. By strategically controlling the angle, color, and intensity of light, the system can eliminate shadows, highlight specific edges, and reveal surface textures that are invisible to the naked eye. This controlled lighting ensures that the captured image has a high contrast between the part features and the background, which is critical for the software to make precise measurements. This foundational technology of advanced optical systems ensures that every measurement is based on a perfectly clear and consistent image, forming the first pillar of defect-free production.

2. Automated Intelligence: From Image to Actionable Data with Sophisticated Software

Capturing a perfect image is only the first step. The true power of an Automatic VMM is unleashed by its sophisticated measurement software. This software utilizes powerful algorithms for edge detection, pattern matching, and geometric dimensioning and tolerancing (GD&T). The process begins with pattern recognition, where the software quickly identifies and locates the part based on a pre-taught model. Once located, the system can automatically execute a complex measurement routine, moving the stage and camera to hundreds of pre-defined points without any human intervention. The software automatically detects edges and calculates dimensions, angles, and complex geometries with micron-level repeatability. Furthermore, this automated inspection process is not just fast; it's completely objective, eliminating the variability and potential for error inherent in manual inspection. This seamless integration of hardware control and data analysis is what makes 100% inspection of high-volume production runs a practical reality.

3. Integration and Reliability: The Backbone of a Zero-Defect Strategy

For an Automatic VMM to be effective in a high-volume manufacturing environment, it must be more than just a standalone measuring device; it must be a reliable node in the factory's quality control network. This requires robust mechanical design, such as a stable granite base and precision guide rails, to ensure long-term stability and vibration resistance. Moreover, seamless seamless integration into the production workflow is key. This involves compatibility with factory networks for real-time data upload to a central Quality Management System (QMS), enabling statistical process control (SPC) and immediate feedback to the production line. The ultimate goal is a closed-loop system where measurement data can trigger automatic adjustments in machining centers, preventing the production of out-of-spec parts. This level of industrial automation, supported by unwavering mechanical and software reliability, transforms the VMM from a passive inspection tool into an active guardian of quality, making the pursuit of zero defects a sustainable achievement.

Conclusion

In conclusion, achieving zero defects in high-volume production is not a matter of chance but of engineering excellence. Automatic Video Measuring Machines make this possible by combining three critical technological pillars: the visual clarity of advanced optical systems, the objective intelligence of sophisticated measurement software, and the unwavering reliability required for seamless integration into automated production lines. Together, these technologies create a robust and scalable solution for ensuring that every single part that leaves the factory meets the highest standards of quality.