The Engineering Behind HC’s High-Speed Response Joystick Controllers

2026-01-21 12:22The Engineering Behind HC’s High-Speed Response Joystick Controllers

Advanced Sensing and Signal Processing

The hallmark of a high-performance industrial joystick is its ability to translate minute operator inputs into immediate, precise, and smooth machine responses. HC's joystick controllers achieve this through the strategic implementation of non-contact sensing technologies, such as Hall Effect or high-resolution magnetic encoders. Unlike traditional potentiometers that rely on physical contact and are prone to wear and signal noise, these advanced sensors detect the subtle changes in a magnetic field caused by the joystick's movement without any physical contact. This fundamental design choice eliminates mechanical friction and the associated lag, providing a foundation for instantaneous response. However, the raw signal from the sensor is just the beginning. HC integrates sophisticated signal processing algorithms directly into the controller. These algorithms filter out environmental noise, such as electromagnetic interference (EMI) from nearby motors or drives, and compensate for minor variations, ensuring that the output signal is both stable and accurate. This combination of robust sensing and intelligent signal conditioning is the first critical layer in delivering the "high-speed response" that defines HC's products, ensuring that machine movement is a seamless extension of the operator's intent.

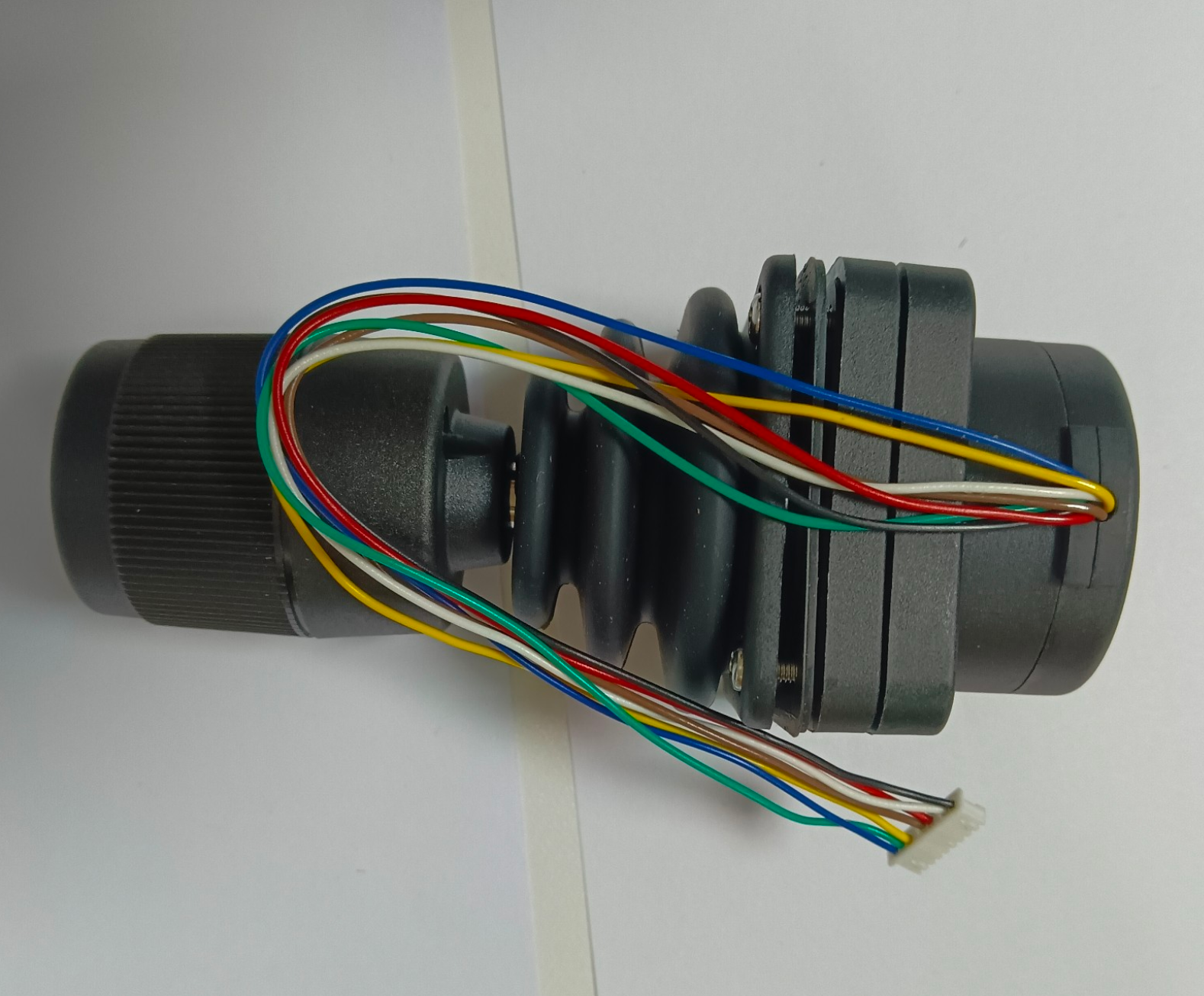

Ergonomic and Mechanical Design for Optimal Control and Durability

Responsiveness is not solely an electronic characteristic; it is also deeply rooted in the physical and ergonomic design of the joystick. HC engineers the mechanical components—including springs, cams, and bearings—to provide precise tactile feedback and a consistent return-to-center force. This careful calibration creates a natural "feel" that allows operators to make fine adjustments with confidence, reducing fatigue and enhancing control accuracy during prolonged use. The mechanical design also dictates the joystick's deflection range and the potential for customizable force profiles. For instance, a variable resistance mechanism can be implemented to require more force for larger deflections, giving operators a greater sense of control at the limits of the movement range. Furthermore, the entire assembly is built to withstand the harsh conditions of industrial environments. High-quality seals (often rated IP65, IP66, or higher) protect the internal electronics from dust, moisture, and coolant ingress. The use of ruggedized materials for the handle and housing ensures impact resistance and long-term durability, meaning the high-speed response and precise feel are maintained over millions of operational cycles, even in the most demanding applications like CNC shot peening or control of heavy machinery.

System Integration and Customization for Application-Specific Performance

The ultimate test of a joystick's engineering is its seamless integration into a broader control system. HC's joystick controllers are designed with this systems approach in mind. They support a range of industry-standard communication protocols, such as CANopen, Profibus, or Ethernet/IP, allowing for straightforward connection to Programmable Logic Controllers (PLCs) and other automation components. This enables the high-speed response to be effectively translated into coordinated multi-axis machine movements. Beyond standard protocols, HC offers significant customization capabilities. The response curve—the relationship between the joystick's physical position and the output signal—can be programmed to be linear, logarithmic, or application-specific. This allows the joystick's behavior to be perfectly tailored to the kinematics of the machinery it controls, whether it's for precise, slow-speed positioning of a CMM or rapid, agile movement of a robotic arm. This ability to fine-tune the controller's profile ensures that the high-speed response is not just fast, but also perfectly suited to the specific task, maximizing both productivity and operational safety.

In summary, the high-speed response of HC's joystick controllers is not an isolated feature but the result of a holistic engineering philosophy. It is achieved through the synergistic integration of non-contact sensing technology, intelligent signal processing, ergonomic mechanical design, and robust system integration capabilities. This meticulous attention to detail at every stage—from the initial sensor signal to the final machine action—ensures that these controllers provide unparalleled control, durability, and adaptability. By perfecting the interface between human operators and complex machinery, HC's engineering empowers industries to achieve new levels of productivity, precision, and safety.