Motor Components Thinner Than a Human Hair

2026-01-01 17:20Motor Components Thinner Than a Human Hair

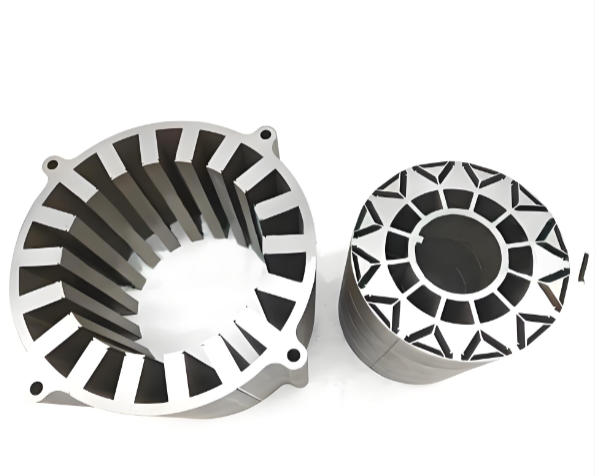

The Engineering Marvel of Ultra-Thin Laminations

At the heart of every high-efficiency electric motor lies a component most people never see: the lamination stack. These are not simple metal pieces; they are precisely engineered thin steel sheets, often thinner than a human hair, that are stacked together to form the motor's stator and rotor. The reason for this intricate design is to combat a hidden enemy of motor efficiency: eddy currents. When a solid metal core is exposed to the motor's rapidly changing magnetic fields, it acts like a short-circuited turn, generating swirling currents that produce significant heat and waste energy. By using ultra-thin, insulated laminations, the path for these parasitic currents is dramatically disrupted. Each lamination is coated with a microscopic insulating layer, effectively confining eddy currents to minute loops within each individual layer. This precise approach to managing electromagnetic phenomena is what allows modern EV motors to achieve exceptional efficiency ratings, often exceeding 95%, directly translating into longer driving range. The pursuit of this efficiency begins with the flawless manufacturing of each single lamination, a process demanding precision at the micron level.

Where Microns Define Performance

The performance of the entire motor is critically dependent on the precision of these hair-thin laminations. This is where high-tolerance manufacturing becomes non-negotiable. As noted in the background material, these components are produced to "high-precision tolerances" to ensure optimal performance under advanced electrical requirements. The process begins with specialized thin-gauge electrical steel. Using advanced precision die-cutting or stamping processes—executed on high-end CNC equipment—the steel is punched into the precise shapes required for the motor's magnetic circuit. The cleanliness of the cut is paramount; even a microscopic burr can bridge the insulation between layers, creating electrical shorts that undermine the entire purpose of the laminations. Furthermore, the precise shape of the laminations—including the intricate slots that will hold the copper windings—must be perfectly formed. Any imperfection can complicate the automated winding process, affect the magnetic flux distribution, and lead to hotspots that reduce motor life. This level of precision, often measured in microns, is what separates a high-performance, reliable EV motor from a mediocre one, enabling the creation of components with weights as low as those mentioned in the background material.

Quality Assurance in the Realm of the Minute

Achieving and maintaining such incredible precision at the volumes required by the automotive industry is only possible through fully automated production and rigorous quality control. The background material highlights a commitment to quality with "100% CCD inspection systems, achieving zero PPM defects." This statement is crucial for components of this scale. High-resolution CCD (Charge-Coupled Device) cameras are integrated directly into the production line, performing automatic visual inspections on every single lamination or stacked core. They check for micro-burrs, dimensional inaccuracies, and imperfections in the insulating coating that would be impossible for the human eye to detect consistently. This 100% inspection rate is essential for achieving the goal of zero Defects Per Million (PPM), a standard demanded by top-tier automotive suppliers. This relentless focus on quality control at the component level is what builds the foundation for the extreme reliability and durability that consumers expect from their electric vehicles. It ensures that every motor built with these precision laminations delivers the silent, powerful, and efficient performance that defines the EV driving experience, proving that monumental achievements in sustainability are built upon attention to the smallest details.