Y-axis 4-way vertical machining center

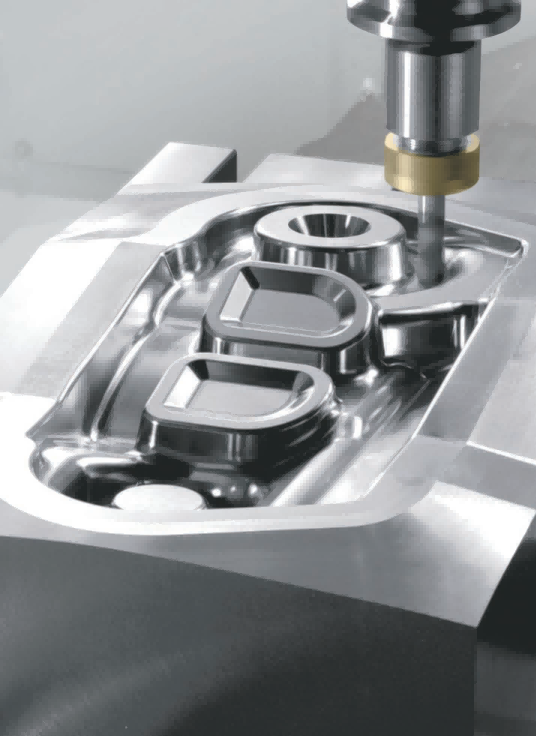

In the field of high-efficiency precision machining, the Y-axis 4-way vertical machining center stands out as the preferred equipment for complex component processing due to its exceptional rigidity and stability.

- HC

- CHINA

- 1 MONTH

- 1000/MONTH

- Information

- Download

The Y-axis 4-way vertical machining center adopts a four-rail Y-axis design, significantly enhancing the machine's torsional resistance and ensuring machining accuracy even under heavy cutting conditions. Whether for automotive molds, aerospace structural components, or precision electronic parts, the Y-axis 4-way vertical machining center delivers outstanding dynamic performance to meet high-load machining demands.

The core advantage of the Y-axis 4-way vertical machining center lies in its four-rail support structure. Compared to traditional dual-rail designs, the Y-axis 4-way vertical machining center effectively suppresses cutting vibrations, extending tool life. Additionally, the Y-axis 4-way vertical machining center is equipped with a high-speed spindle and intelligent cooling system, maintaining stable performance even during prolonged continuous machining. For modern manufacturing enterprises pursuing high efficiency and precision, the Y-axis 4-way vertical machining center is undoubtedly the ideal choice to enhance productivity and quality.

Furthermore, the Y-axis 4-way vertical machining center supports automation integration, allowing seamless connection with robotic arms or AGV systems to achieve unmanned production. The modular design of the Y-axis 4-way vertical machining center also facilitates future upgrades and maintenance, ensuring long-term optimal performance. Whether for mass production or high-difficulty complex machining, the Y-axis 4-way vertical machining center meets diverse requirements with superior performance, helping enterprises gain a competitive edge in the market.