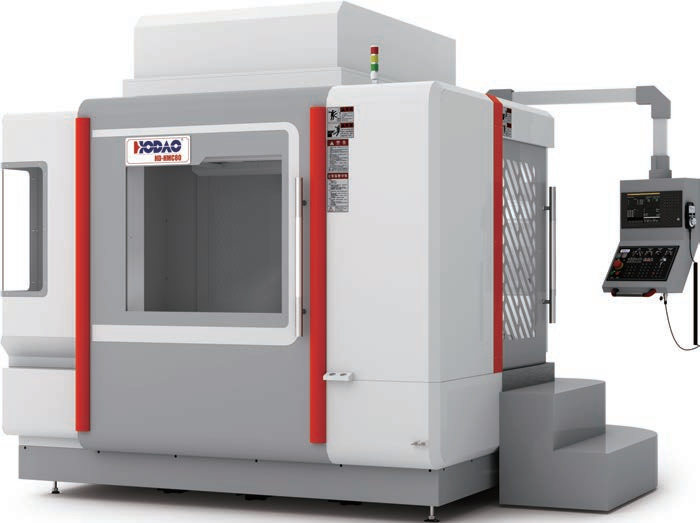

Horizontal Machining Center2

In modern precision manufacturing, the Horizontal Machining Center (HMC) has become the preferred equipment for machining heavy-duty parts, box-type workpieces, and complex structural components due to its outstanding stability and high-efficiency processing capabilities.

- HC

- CHINA

- 1 MONTH

- 1000/MONTH

- Information

- Download

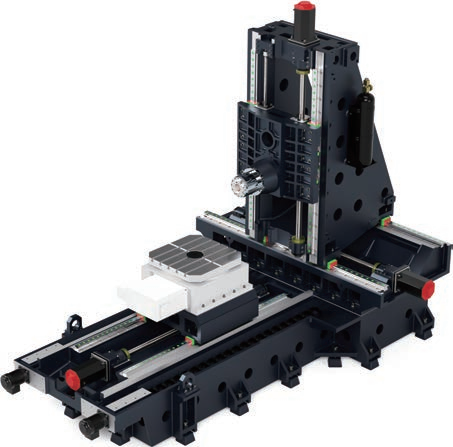

The Horizontal Machining Center (HMC) adopts a horizontal spindle layout combined with a high-rigidity bed structure, enabling high-torque cutting, making it particularly suitable for mass production in industries such as aerospace, automotive manufacturing, and energy equipment.

Compared to vertical machines, the Horizontal Machining Center (HMC) offers superior chip evacuation and more stable machining accuracy. The Horizontal Machining Center (HMC) typically features a CNC rotary table, enabling multi-face machining in a single setup, significantly reducing workpiece repositioning errors and improving production efficiency. Additionally, the enclosed protective design of the Horizontal Machining Center (HMC) effectively minimizes coolant splashing, ensuring a clean and safe operating environment.

In automated production lines, the Horizontal Machining Center (HMC) can be easily integrated with robots or gantry manipulators to achieve unmanned continuous production, meeting the high-efficiency and high-precision demands of modern smart manufacturing. Whether for large cast iron parts or high-hardness alloy materials, the Horizontal Machining Center (HMC) delivers exceptional cutting performance and long-term stability, helping enterprises enhance competitiveness and reduce overall production costs.