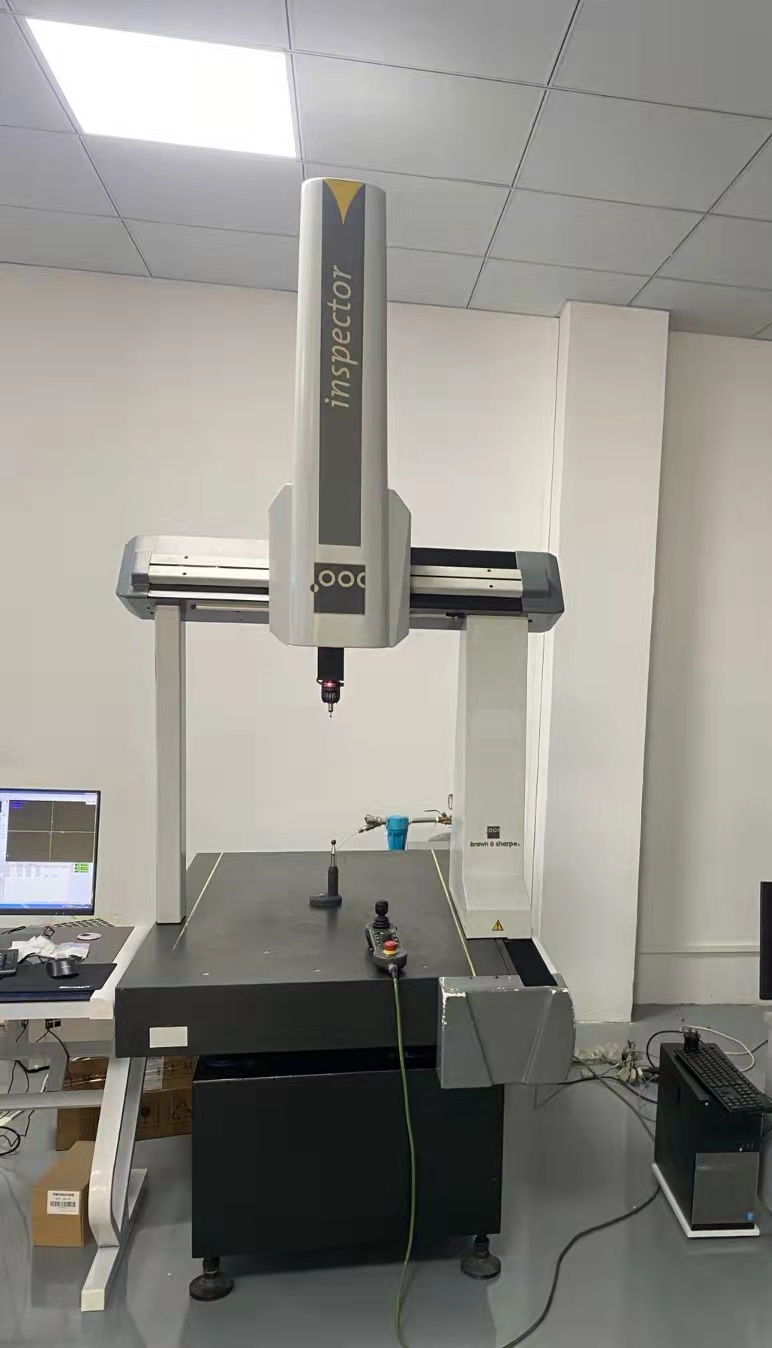

Coordinate measuring machine

The Coordinate Measuring Machine operates by using a probing system to collect data points from the surface of a workpiece, creating a detailed 3D representation of its geometry. Equipped with high-accuracy sensors and sophisticated software, the machine measures complex shapes, contours, and features with micron-level precision. The integration of CAD (Computer-Aided Design) compatibility allows for direct comparison between measured data and design specifications, enabling rapid identification of deviations and ensuring compliance with quality standards.

- HC

- CHINA

- 1 MONTH

- 40000/MONTH

- Information

- Download

A standout feature of the Coordinate Measuring Machine is its versatility in measuring a wide range of materials and part sizes. Available in various configurations, including bridge, gantry, and portable models, the machine adapts to different measurement tasks and environments. The inclusion of automated probing systems and robotic arms enhances efficiency, particularly in high-volume production settings, while advanced temperature compensation ensures reliable performance in varying environmental conditions.

The Coordinate Measuring Machine is designed with user-friendly interfaces and intuitive software, simplifying operation and data analysis. The machine’s robust construction and vibration-dampening features ensure stability and accuracy during measurement processes. Additionally, the integration of cloud-based data management systems facilitates seamless collaboration and traceability across production teams.

In summary, the Coordinate Measuring Machine is an indispensable tool in modern manufacturing and product development, offering unparalleled accuracy, versatility, and efficiency. By providing precise dimensional analysis and quality assurance, the machine empowers industries to maintain high standards of product integrity and performance, driving innovation and competitiveness in global markets.