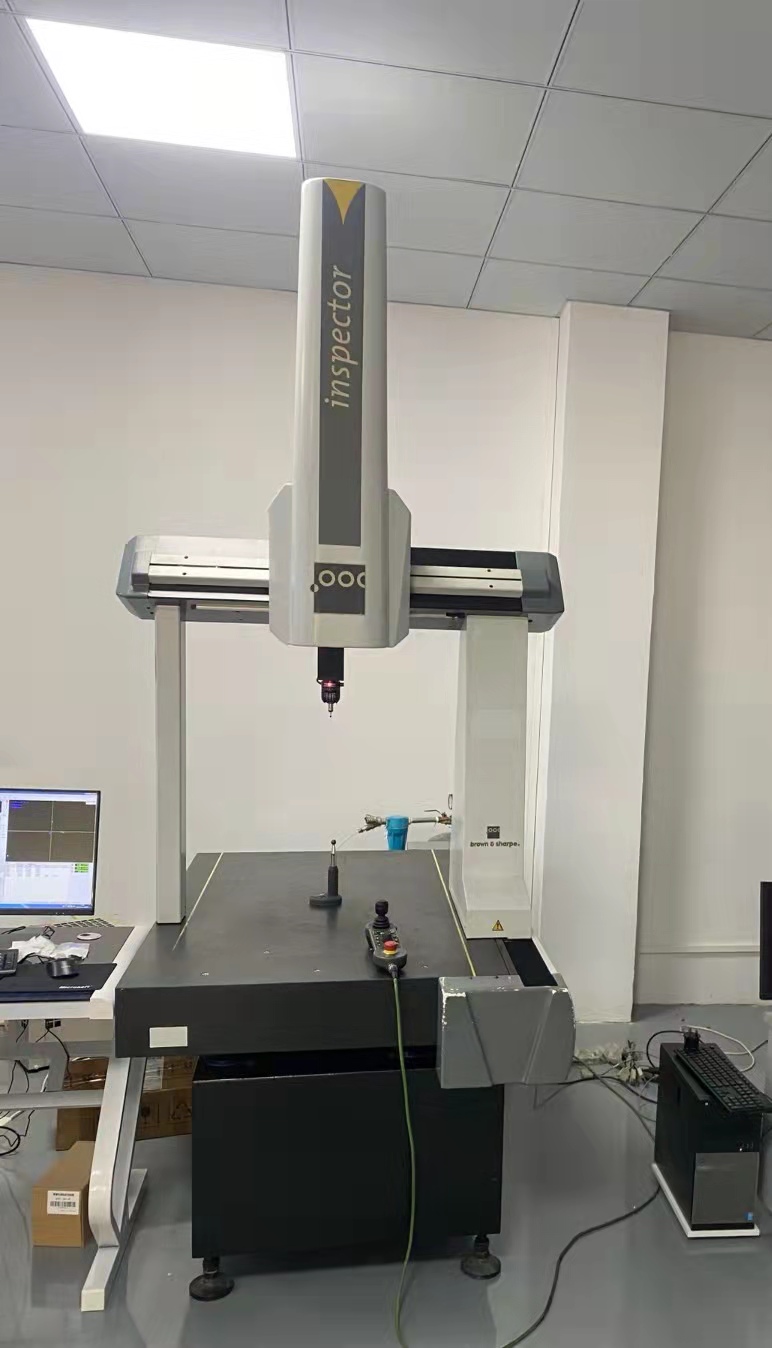

Cantilever coordinate measuring machine

The Cantilever Coordinate Measuring Machine utilizes advanced probing technology to capture precise data points from the surfaces of workpieces, generating detailed 3D models for quality inspection and verification. The cantilever structure allows unobstructed access to all sides of a workpiece, simplifying the measurement of complex geometries and reducing setup time. High-resolution sensors and robust motion control systems ensure micron-level accuracy, even for intricate features and large dimensions.

- HC

- CHINA

- 1 MONTH

- 40000/MONTH

- Information

- Download

A key advantage of the Cantilever Coordinate Measuring Machine is its adaptability to diverse measurement tasks. The open design accommodates a variety of part shapes and sizes, while customizable probing options enhance versatility. Integrated software solutions enable seamless comparison of measured data with CAD models, facilitating rapid identification of deviations and ensuring compliance with stringent quality standards. Advanced temperature compensation and vibration-dampening features maintain measurement reliability in dynamic industrial environments.

The Cantilever Coordinate Measuring Machine is engineered for ease of use and operational efficiency. User-friendly interfaces and intuitive software streamline measurement processes, while automated probing systems reduce manual intervention and increase throughput. The machine’s robust construction ensures long-term durability, and modular components allow for easy maintenance and upgrades.

In summary, the Cantilever Coordinate Measuring Machine represents a significant advancement in metrology technology, offering unmatched accessibility, precision, and flexibility. By enabling accurate and efficient dimensional analysis, this machine supports industries in maintaining high-quality standards, optimizing production processes, and driving innovation in product development.