- Home

- >

- Products

- >

- T-40 Infrared Probe

- >

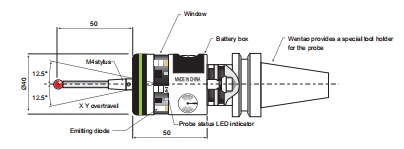

T-40 Infrared Probe

Featuring rapid response, T-40 Infrared Probe achieves millisecond-level temperature detection, making it ideal for demanding applications such as high-temperature rolling and semiconductor processing—ensuring both production safety and efficiency.

- HC

- CHINA

- 1 MONTH

- 2000/MONTH

- Information

- Download

It can be used with the T-50 Receiver or T-50A Receiver.

Feature Description

1、 Precise measurement, positioning of workpieces, and automatic correction of coordinate systems;

2、 Quick positioning of fixture locations, reducing manual adjustment time;

3、Simplifies fixture design and reduces fixture costs;

4、 Conducts first-piece on-machine measurement checks without the need for a machine;

5、 Improves productivity and consistency of batch processing dimensions;

6、 Measures during cyclic processing, monitors workpiece dimensions and positions, and automatically corrects;

7、Shortens machine auxiliary time and improves production efficiency;

8、 Easy installation, suitable for all domestic and international CNC control systems: Fanuc, Siemens, Mitsubishi, Xindai, Huazhong, Weihong,Baoyuan, Fagor, etc.

In the fields of precision manufacturing and automated machining, the T-40 Infrared Probe stands out as a core equipment for dimensional inspection and position calibration, thanks to its infrared non-contact measurement technology. The T-40 Infrared Probe utilizes a high-sensitivity infrared sensing system to quickly identify workpiece contours, hole positions, and surface features, eliminating potential scratches or wear caused by traditional contact probes. This makes the T-40 Infrared Probe particularly suitable for measuring precision components, brittle materials, and high-gloss surfaces.

With excellent anti-interference capabilities, the T-40 Infrared Probe maintains stable performance even in environments with cutting fluid splashes or dust, ensuring reliable data collection. When integrated with CNC systems, the T-40 Infrared Probe automatically compensates for machine tool thermal deformation errors, improving machining accuracy and consistency while significantly reducing manual re-inspection time.

Whether for in-line inspection of automotive molds or quality control of complex aerospace surfaces, the T-40 Infrared Probe delivers high-precision measurements with millisecond-level response speeds, empowering businesses to achieve intelligent, unmanned production upgrades!