ONLINE DETECTION SCHEME

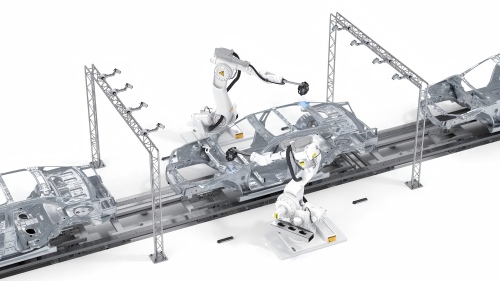

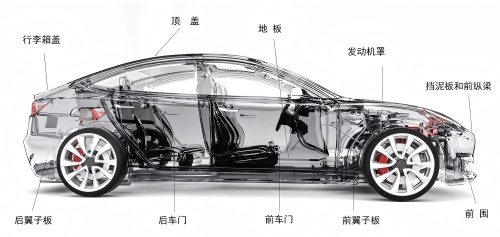

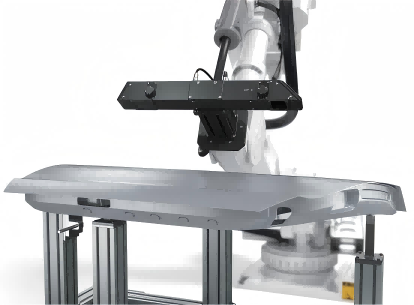

HC's ONLINE DETECTION SCHEME, built upon decades of expertise in optical 3D/2D measurement and robotic guidance, has been successfully implemented in flexible automated production lines for automotive body-in-white. Seamlessly integrated with welding lines, this solution achieves efficient comprehensive inspection. Employing modular probes and the OMS II system, the ONLINE DETECTION SCHEME precisely identifies and classifies defects including dents and waves in sheet metal components while fully meeting production cycle requirements. Documented cases confirm that this ONLINE DETECTION SCHEME has served multiple automotive body manufacturers, significantly enhancing quality verification automation and production efficiency through its high precision and rapid cycle times.

- HC

- CHINA

- 1 MONTH

- 500/MONTH

- Information

- Download

The HC ONLINE DETECTION SCHEME represents a paradigm shift in automotive manufacturing quality control, embedding precision measurement directly into the heart of the production flow. This innovative ONLINE DETECTION SCHEME is engineered to operate in unison with body shop welding lines, creating a fully automated and uninterrupted process from assembly to validation. The core strength of the ONLINE DETECTION SCHEME lies in its seamless integration, which eliminates the need for manual intervention or moving parts to a separate inspection station, thereby guaranteeing that every single body-in-white undergoes a comprehensive and objective evaluation without compromising production cadence. By implementing this robust ONLINE DETECTION SCHEME, manufacturers can achieve a true 100% inspection rate, providing a complete and continuous data stream for real-time process control and immediate corrective actions. The architecture of the ONLINE DETECTION SCHEME is fundamentally designed for resilience and adaptability within the demanding industrial environment, ensuring long-term stability and reliable performance.

At the technological core of the HC ONLINE DETECTION SCHEME is a sophisticated fusion of advanced optical metrology and robotic automation. The ONLINE DETECTION SCHEME utilizes high-resolution 3D sensors and modular probe systems that are robotically guided to perform precise measurements on complex body geometries. This integration allows the ONLINE DETECTION SCHEME to capture millions of data points in a matter of seconds, creating a detailed digital twin of the physical asset for exhaustive analysis. The proprietary algorithms powering the ONLINE DETECTION SCHEME are capable of reliably identifying, classifying, and quantifying a wide array of surface and dimensional defects, including dents, bumps, waves, and shrinkage, with a level of accuracy and repeatability unattainable by manual methods. Furthermore, the ONLINE DETECTION SCHEME incorporates deep learning capabilities that enable the system to continuously improve its defect recognition patterns over time, enhancing the ONLINE DETECTION SCHEME's analytical precision and reducing false calls, which solidifies the ONLINE DETECTION SCHEME's role as a self-optimizing asset on the factory floor.

The operational benefits delivered by the HC ONLINE DETECTION SCHEME translate directly into significant competitive advantages on the production floor. The high-speed, non-contact nature of the ONLINE DETECTION SCHEME ensures that measurement cycles are completed within the strict time constraints of the production takt, effectively eliminating bottlenecks and maximizing throughput. The objective data generated by the ONLINE DETECTION SCHEME provides manufacturing engineers with unparalleled visibility into process variations, enabling root cause analysis and facilitating rapid tooling or robotic path adjustments to prevent the production of non-conforming bodies. This proactive quality assurance, championed by the ONLINE DETECTION SCHEME, drastically reduces scrap and rework costs while ensuring that only products meeting the highest standards proceed to the next assembly stage. The comprehensive reporting and traceability features inherent in the ONLINE DETECTION SCHEME also provide invaluable documentation for compliance and continuous improvement initiatives, making the ONLINE DETECTION SCHEME an indispensable tool for modern smart factories striving for operational excellence and zero-defect manufacturing.