Industrial Computed Tomography

Industrial CT, as a key technology in non-destructive testing, is vital in high-end sectors like aerospace, automotive, and new energy. The company partners with global industry leaders and research institutes, building a strong portfolio of collaboration cases. Advanced imaging algorithms and hardware R&D enable micrometer-level precision scanning. Automated production lines and strict quality control ensure robust manufacturing capability and stable product performance. Sales have grown consistently, expanding market share year after year. Efficient supply chain management maintains ample inventory, allowing quick responses to diverse global client demands.

- HC

- CHINA

- 1 MONTH

- 500/ MONTH

- Information

- Download

Industrial CT Technology: The Core Engine Driving High-End Manufacturing and Precision Inspection

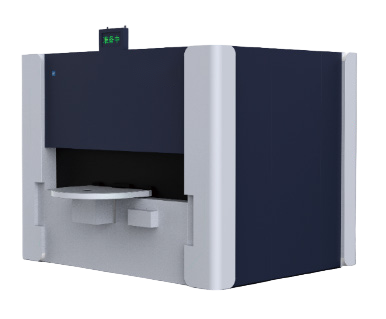

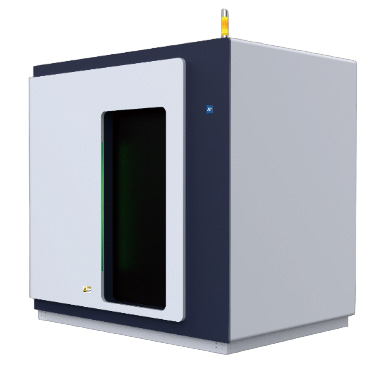

Industrial CT technology, with its exceptional non-destructive testing capabilities, has become an indispensable precision inspection tool in modern high-end manufacturing. Utilizing high-precision X-ray scanning, Industrial CT technology can clearly reveal a product's internal three-dimensional structure, assembly status, and potential defects, covering inspection needs from micron-level electronic components to large, complex aerospace structures. The application of Industrial CT technology has fundamentally transformed the limitations of traditional destructive testing and manual sampling inspection, providing a revolutionary solution for product quality control and process optimization.

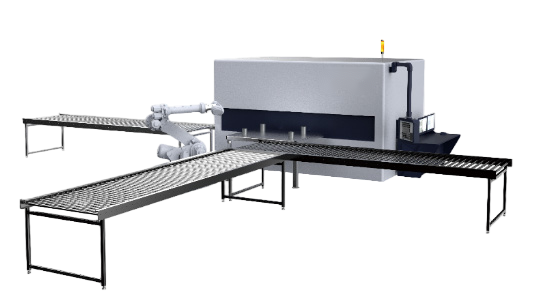

In terms of application scenarios, Industrial CT technology has deeply penetrated numerous critical industrial sectors. In the aerospace field, Industrial CT technology is used to accurately detect internal pores, cracks, and residual stress in core components such as engine turbine blades and ceramic matrix composites, ensuring absolute safety and reliability of aircraft. Within the new energy vehicle industry, Industrial CT technology performs comprehensive scanning of power battery cells, modules, and packs, precisely evaluating electrode alignment, welding quality, and electrolyte distribution, serving as a core method for guaranteeing battery safety and performance. Furthermore, in sectors like precision electronics, medical implants, military equipment, and archaeological artifact restoration, Industrial CT technology similarly plays an irreplaceable role.

Extensive collaboration cases fully demonstrate the market value and reliability of Industrial CT technology. Many of the world's leading automotive manufacturers have integrated Industrial CT technology into their supplier quality assessment systems, establishing it as the gold standard for incoming part inspection. Several major domestic battery enterprises have established joint laboratories with Industrial CT technology suppliers to co-develop specialized inspection and analysis software for lithium-ion batteries. These successful collaboration cases not only drive the iterative升级 of Industrial CT technology but also help end-users significantly improve product yield rates, shorten R&D cycles, and build solid technological barriers.

The advancement of Industrial CT technology is rooted in its continuously innovative R&D technology system. Modern R&D efforts in Industrial CT technology focus on higher-resolution detectors, more intelligent imaging algorithms, and more powerful 3D data processing capabilities. For example, artificial intelligence-based artifact suppression algorithms and automatic defect recognition algorithms极大地 enhance the inspection efficiency and accuracy of Industrial CT technology. R&D technology teams continuously optimize the协同 work of the X-ray source, mechanical motion platform, and digital imaging chain, enabling Industrial CT technology to achieve faster scanning speeds and larger sample capacities, meeting the stringent demands of industrial online inspection.

Robust production capabilities form the solid foundation for translating Industrial CT technology from the laboratory to large-scale application. Leading Industrial CT manufacturers possess highly automated precision assembly production lines and environmentally controlled calibration workshops with constant temperature and humidity. The embodiment of production strength lies not only in整机 assembly but also in the independent design and process control of core components, such as micro-focus X-ray sources and flat-panel detectors. Stringent production quality management systems ensure that every Industrial CT device shipped from the factory exhibits excellent stability, repeatability, and long-term reliability, capable of operating consistently and stably in complex industrial field environments.

Consistently growing sales volume is the most direct proof of the market's high recognition of Industrial CT technology. In recent years, alongside the global manufacturing shift towards intelligence and high quality, the sales volume of Industrial CT equipment has shown a strong upward trend. Especially driven by emerging industries like new energy vehicles, semiconductors, and additive manufacturing (3D printing), the sales volume of Industrial CT technology has increased year after year. The growth in sales volume not only generates considerable economic benefits but also, through the deployment of a vast number of devices, accumulates rich application data that further feeds back into R&D technology and product optimization.

Scientifically managed inventory levels are a key环节 in ensuring the resilience of the Industrial CT industry chain and supply chain, as well as customer response速度. To ensure the timely delivery of global customer orders, Industrial CT manufacturers need to maintain reasonable strategic safety stock levels for core optical components, precision mechanical parts, and specialized chips. By implementing advanced ERP and supply chain management systems, companies can dynamically optimize inventory levels, ensuring the continuity of production and delivery while avoiding capital tie-ups. Adequate inventory of spare parts is also a crucial guarantee for providing customers with efficient after-sales service and technical support.

In summary, Industrial CT technology is deeply empowering intelligent manufacturing and quality innovation with its unique advantages of precision, non-destructiveness, and 3D visualization. From cutting-edge R&D technology and scaled production capabilities to market-driven sales volume and inventory management, Industrial CT technology has established a complete industrial ecosystem. In the future, as technology advances and costs optimize, the application boundaries of Industrial CT technology will further expand, safeguarding production and quality for industries.