5-axis tool presetter

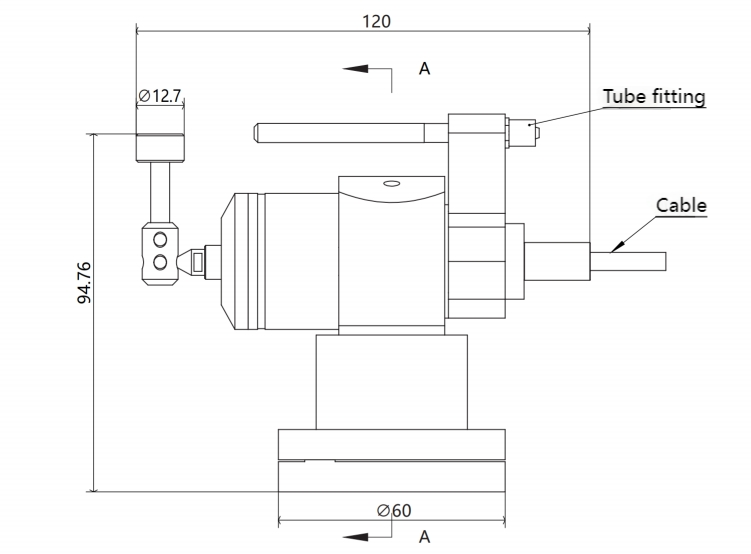

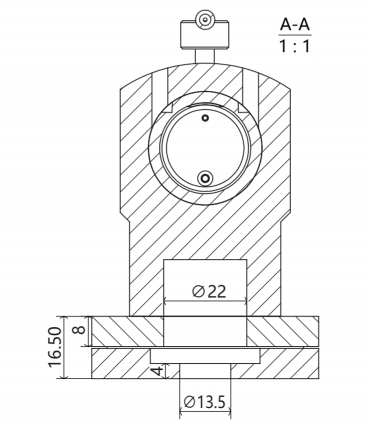

The 5-axis tool presetter (Tool Presetter) is an efficiency booster for CNC machining centers, significantly enhancing production efficiency with its high-precision measurement and rapid tool setting capabilities. Its 5-axis probing technology accurately detects tool radial, axial, and tip positions, ensuring dimensional consistency in machining—especially ideal for high-precision processing of complex workpieces.

- HC

- CHINA

- 1 MONTH

- 1000/MONTH

- Information

- Download

In modern precision machining, the 5-axis tool presetter revolutionizes CNC machining efficiency with its comprehensive measurement capabilities. This high-precision equipment utilizes unique 5-axis measurement technology to simultaneously detect tool runout, axial deviation, tip position, tool length, and diameter, ensuring machining accuracy remains at micron-level consistency.

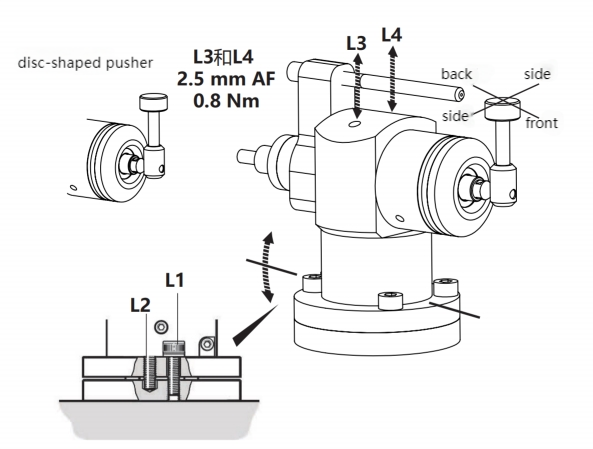

For complex part machining requiring frequent tool changes, the 5-axis tool presetter demonstrates irreplaceable advantages. Operators simply mount the tool on the 5-axis tool presetter's measuring station, and the equipment automatically completes all critical dimension inspections while generating precise tool offset data. This efficient measurement method is particularly suitable for demanding applications like automotive components and medical devices where dimensional tolerances are critical.

The rugged design of the 5-axis tool presetter enables reliable operation in diverse workshop environments. Its fully enclosed structure effectively shields against cutting fluid and metal chips, ensuring long-term measurement stability. In mass production environments, the 5-axis tool presetter can help workshops reduce tool setup time by up to 70%, significantly improving equipment utilization rates.

With the advancement of smart manufacturing, the 5-axis tool presetter is becoming standard equipment in modern machining workshops. Whether for small-batch prototyping or large-scale production, the 5-axis tool presetter delivers remarkable accuracy improvements and efficiency optimization for machining enterprises.